Ceramics Cu

Ceramics Cu

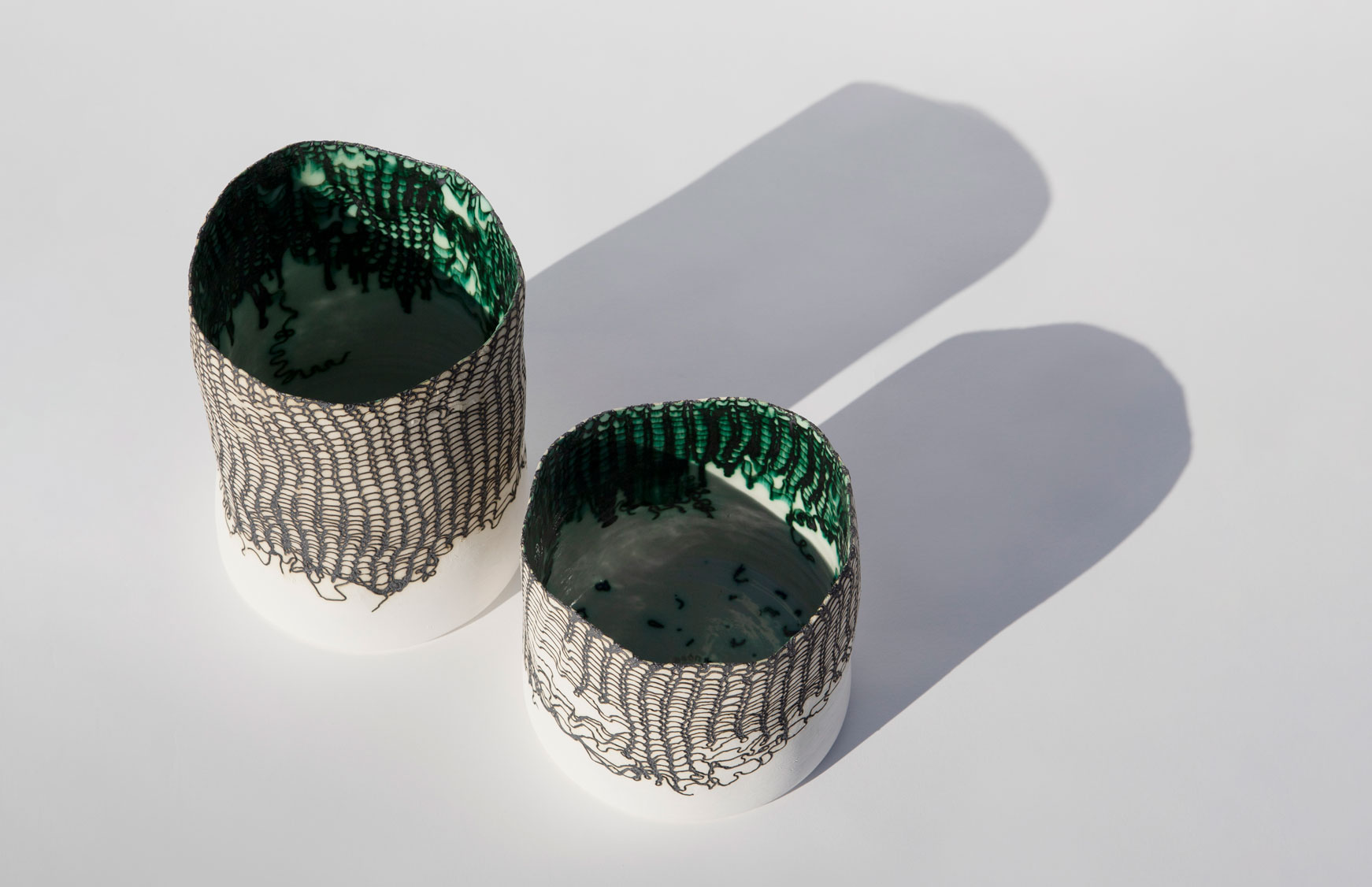

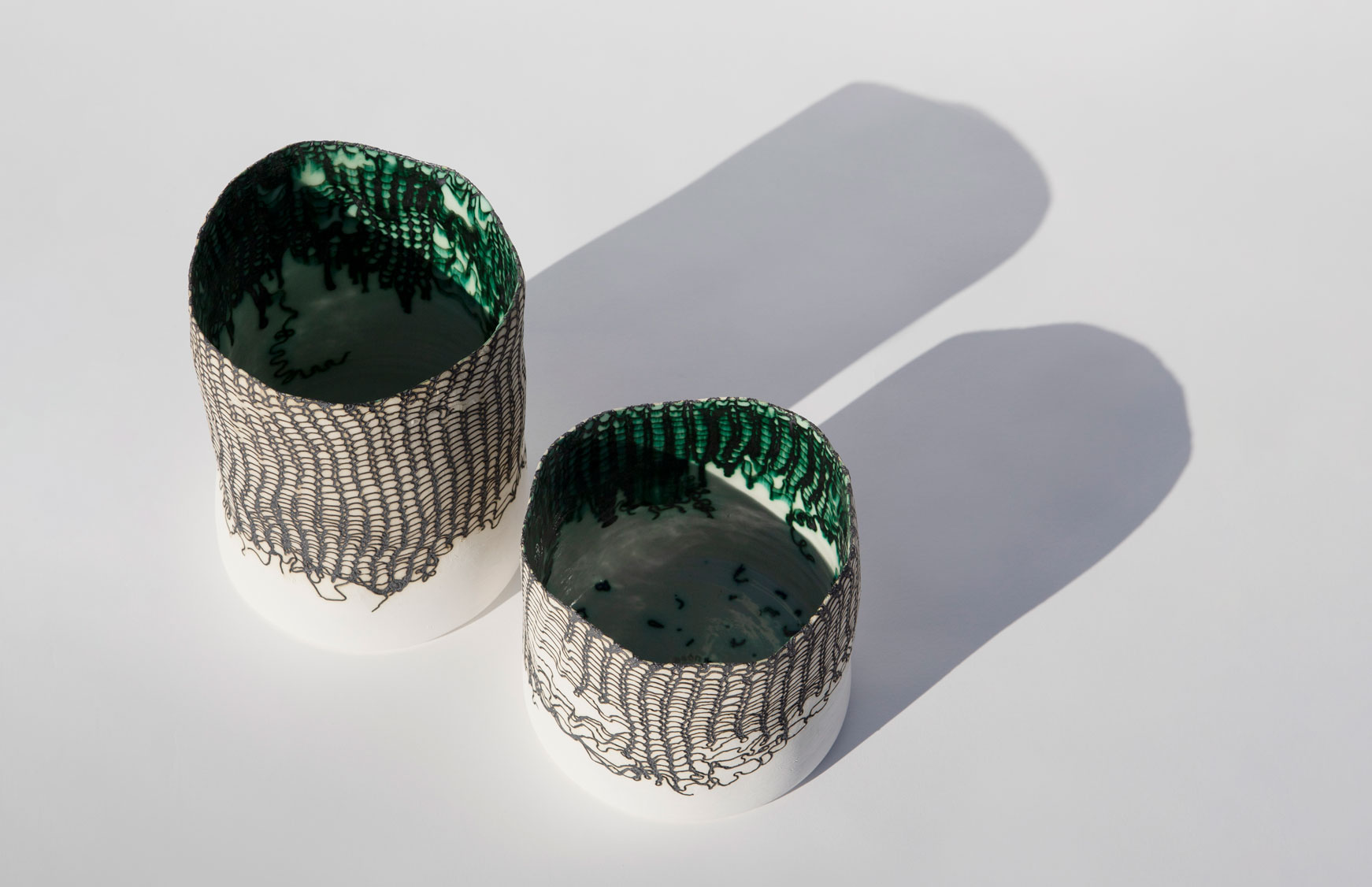

Ceramics Cu, is a collection of pieces created with ceramic, copper and silica. Through an innovative technique, each piece is transformed into a new object in which colors and ornamental lines emerge in a singular and unique way.

Basketry and ceramics are two of the oldest crafts in the world, there are traces of pieces that demonstrate the interrelationship between these two trades. With this project, we seek to resume those first experiments that mix both techniques.

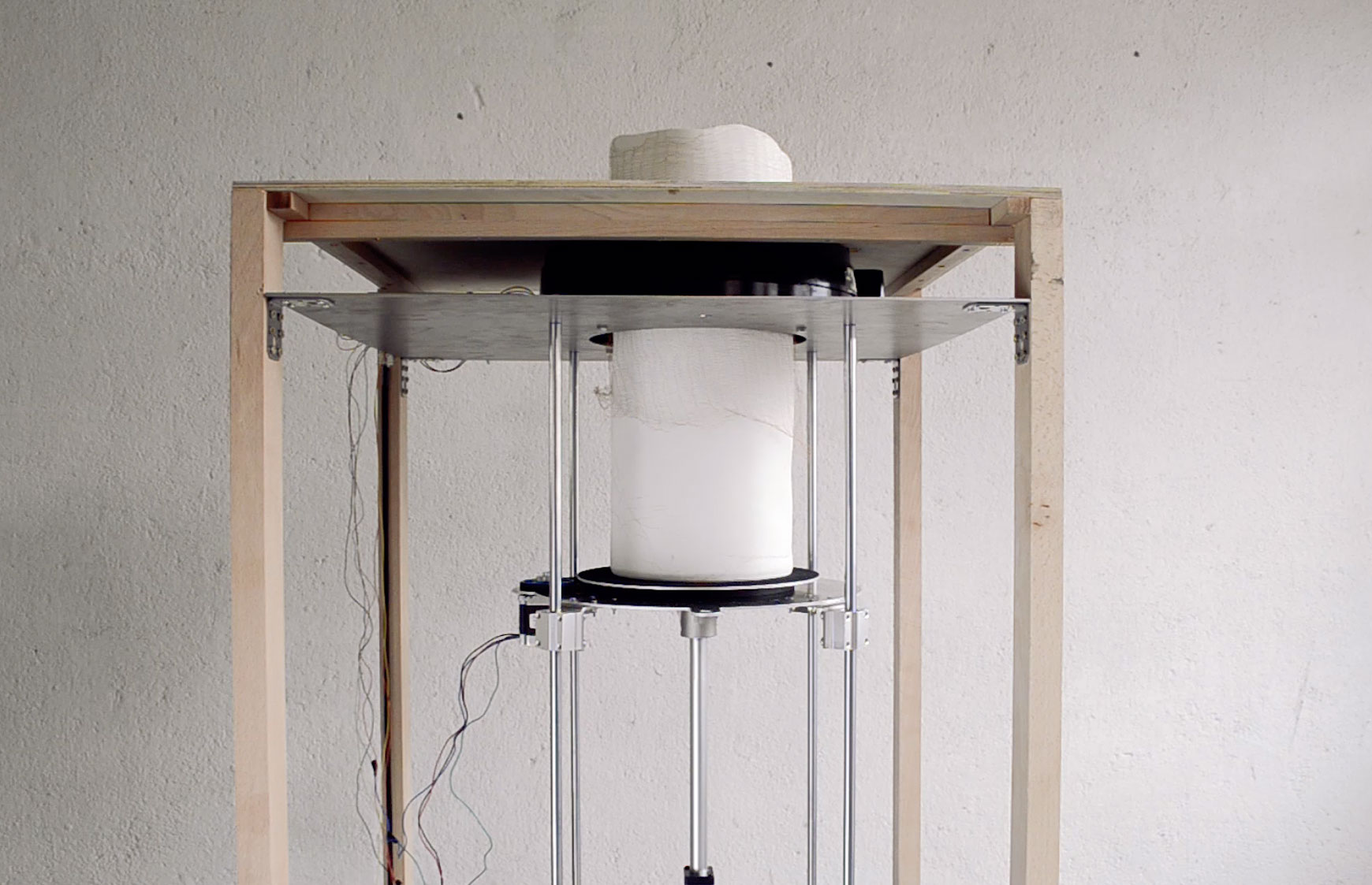

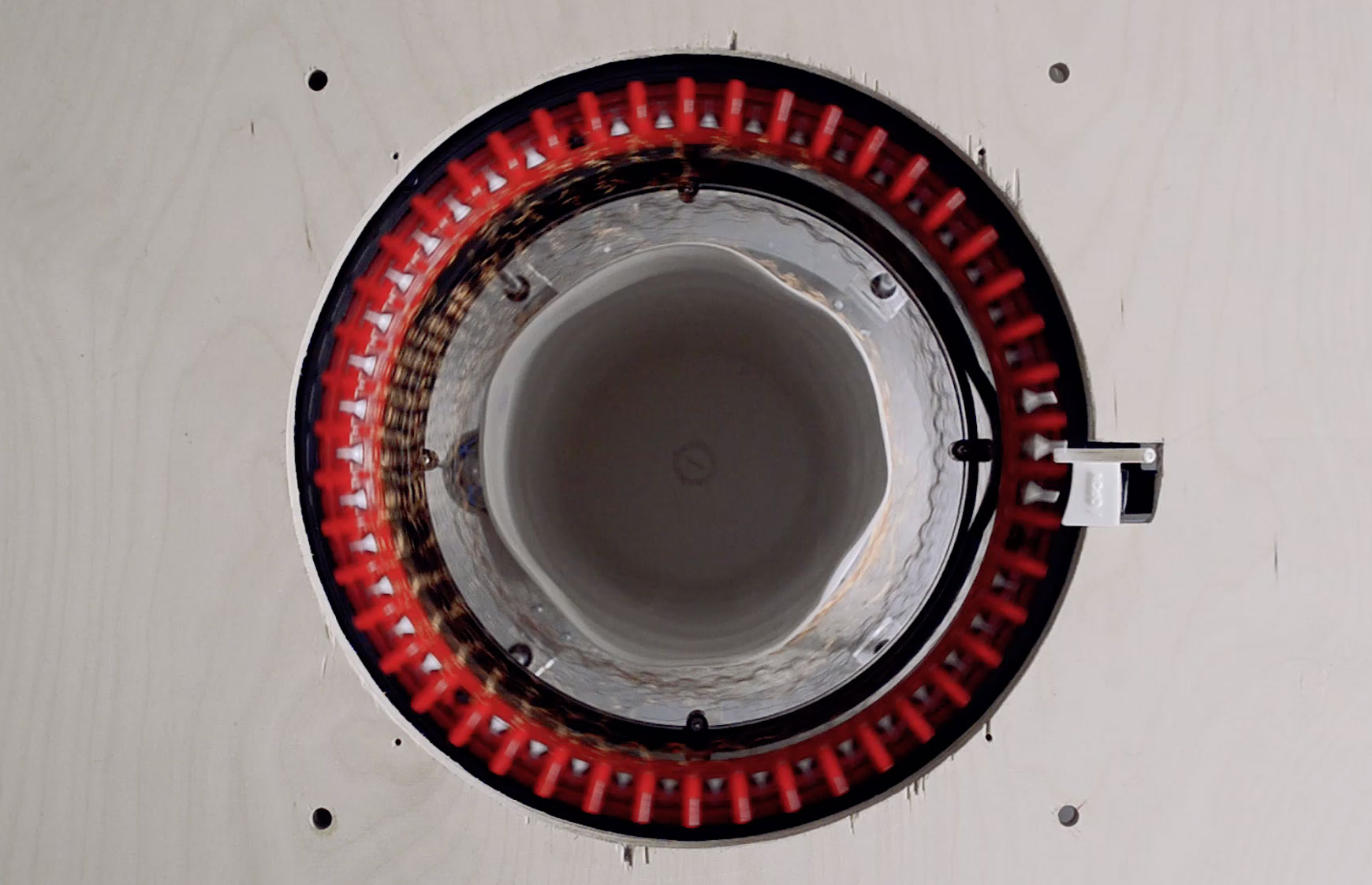

- Ceramics Cy by Teresa Piensos Gómez

- Ceramics Cy by Teresa Piensos Gómez

- Ceramics Cy by Teresa Piensos Gómez

- Ceramics Cu composition. Photo by ACdO

- Small details of the inner surface of Ceramics Cu vases. Photo by

- Work space decoration with Ceramics Cu. Photo by Anette Aulestia

- Ceramics Cu in the morning sunlight. Photo by Anette Aulestia

- Ceramics Cu composition with leaves and flowers. Photo by Aina Lütken

- Ceramics Cu display at Casa Carvajal. Photo by Manolo Yllera

- Ceramics Cu vase on a living room table. Photo by Anette Aulestia

- Ceramics Cu display at Rossana Orlandi (Milan). Photo by ACdO

- Ceramics Cy by Teresa Piensos Gómez

- Ceramics Cy by Teresa Piensos Gómez

- Ceramics Cy by Teresa Piensos Gómez

- Ceramics Cu composition. Photo by ACdO

- Small details of the inner surface of Ceramics Cu vases. Photo by

- Work space decoration with Ceramics Cu. Photo by Anette Aulestia

- Ceramics Cu in the morning sunlight. Photo by Anette Aulestia

- Ceramics Cu composition with leaves and flowers. Photo by Aina Lütken

- Ceramics Cu display at Casa Carvajal. Photo by Manolo Yllera

- Ceramics Cu vase on a living room table. Photo by Anette Aulestia

- Ceramics Cu display at Rossana Orlandi (Milan). Photo by ACdO